Cost Reductions

Embr Labs

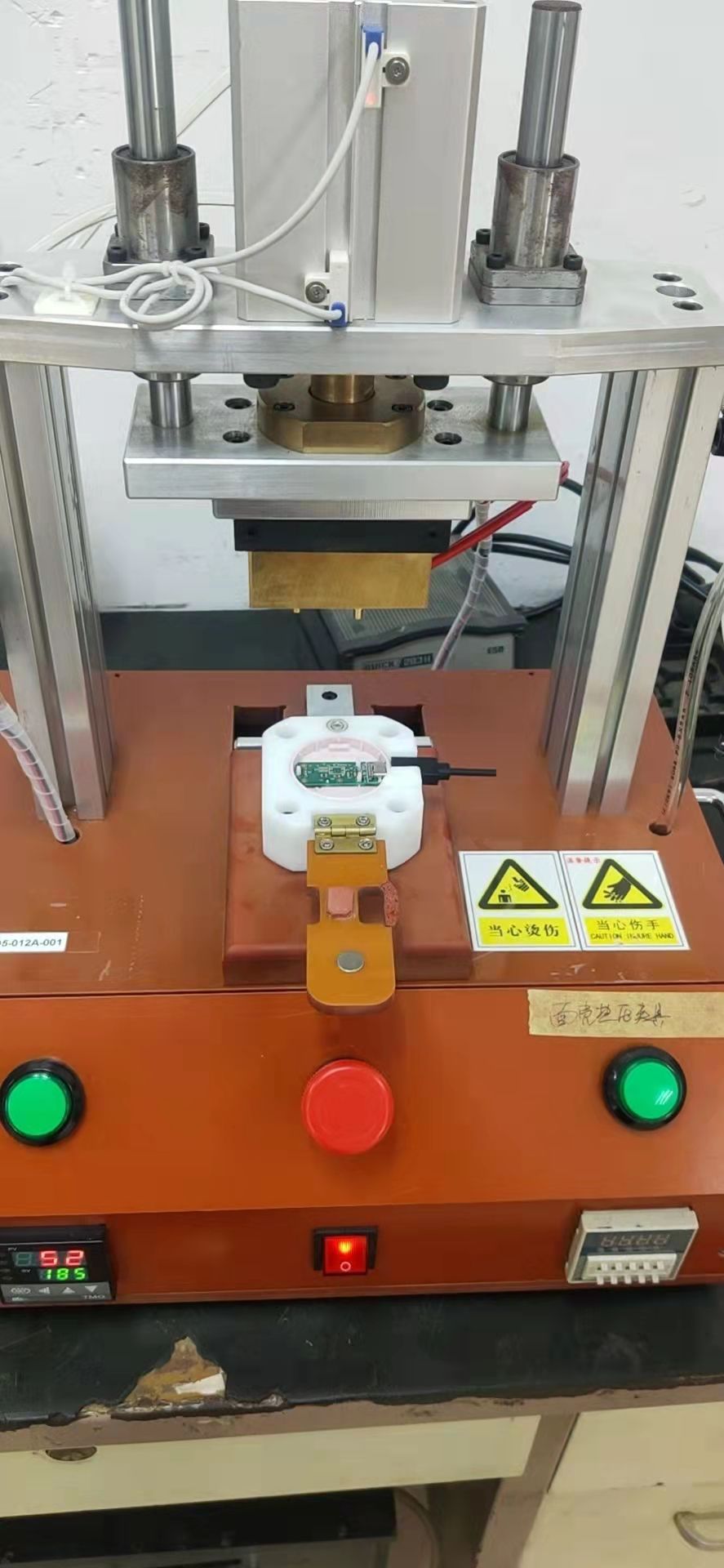

Led a cost reduction initiative on the Embr Wave 2 charger, tackling two parallel workstreams: redesigning the plastic housing to accommodate a new USB-C port while reducing manufacturing costs, and introducing pad printing to replace laser etching on housing markings.

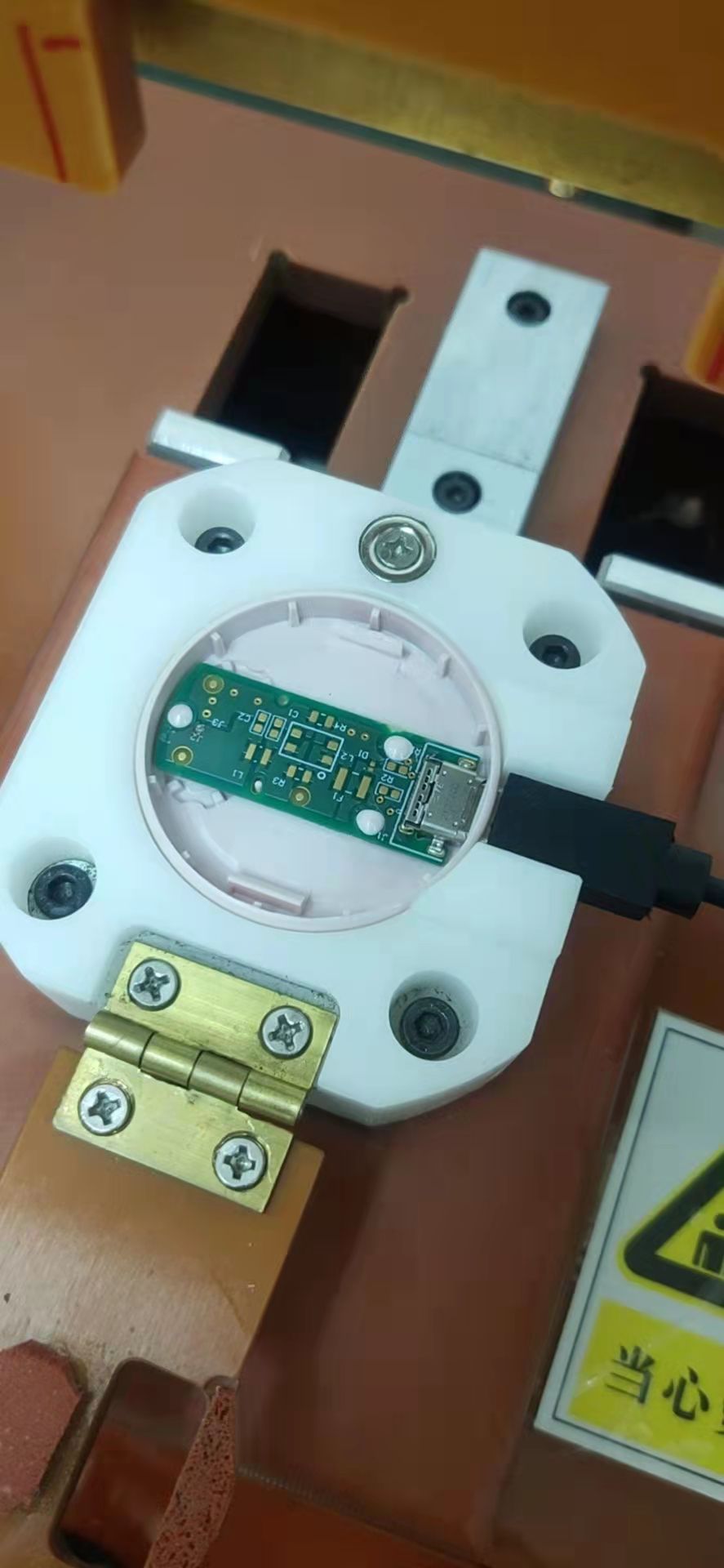

USB-C Transition & Tooling Revision

The primary goal was to accommodate a new USB-C connector while simultaneously reducing unit cost. I revised the injection-molded housing tooling to relax tight tolerances and added alignment features directly to the plastic that register the PCB during assembly — eliminating the need for manual positioning and reducing assembly time.

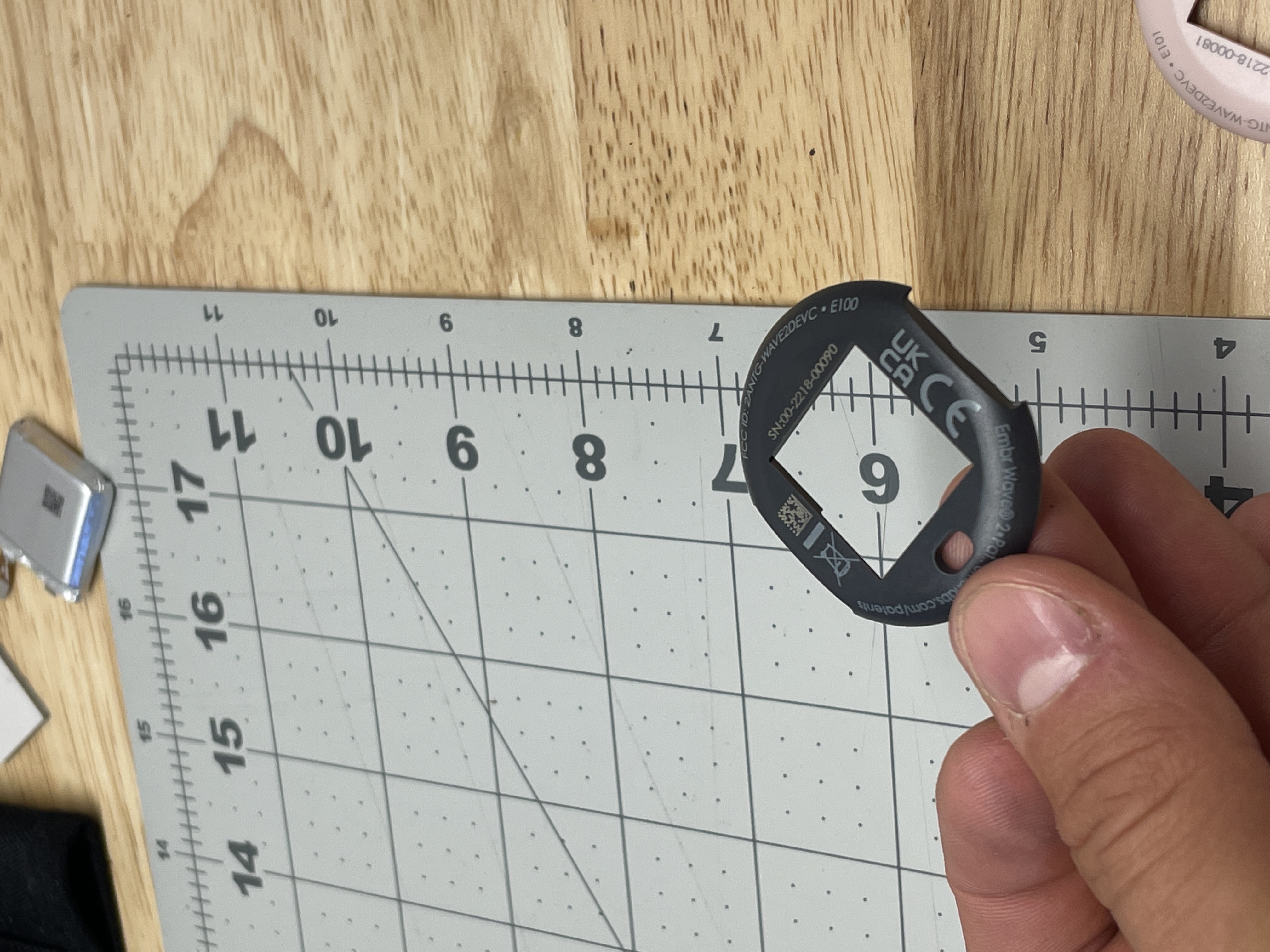

Pad Print Markings

Replaced laser etching with pad printing for regulatory markings and branding on the housing. Pad printing improved cosmetic quality with cleaner, more consistent marks while significantly reducing per-unit marking costs at production volume.