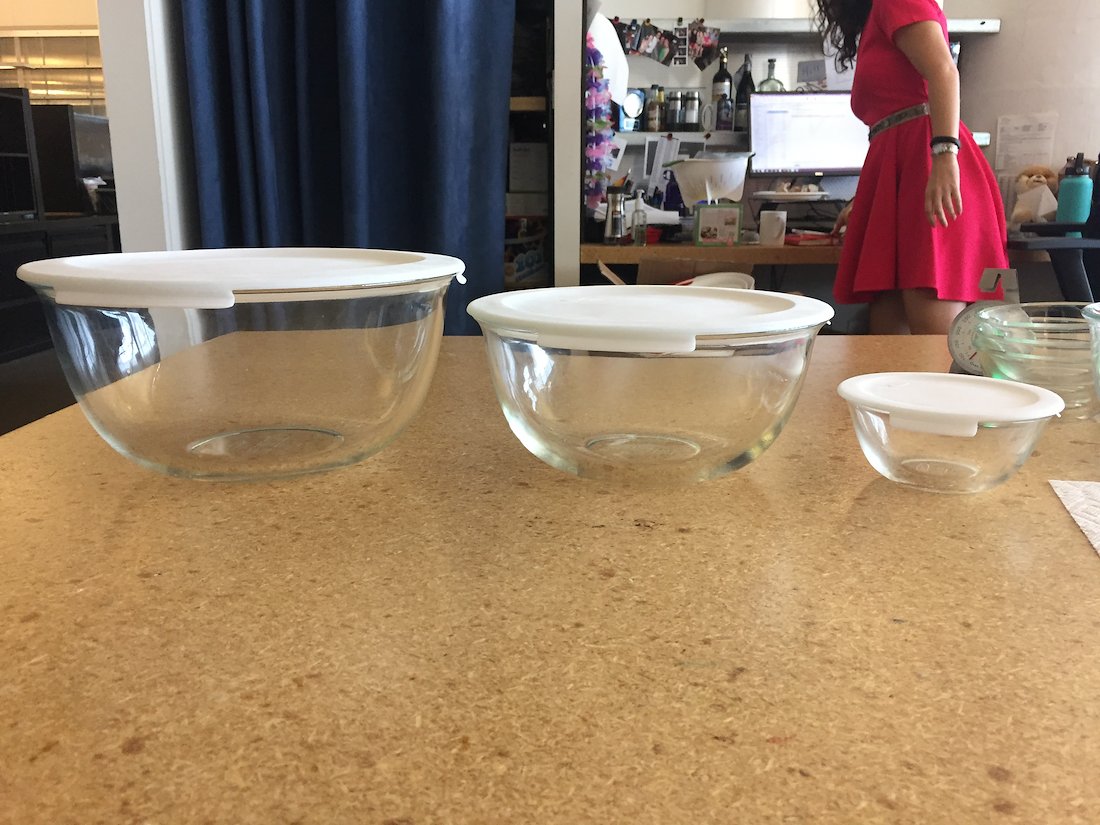

Glass Bowls

OXO

This project involved learning glass molding and tempering processes while managing inherent tolerance challenges. The core challenge was designing low-cost, food-safe, single-piece lids that seal containers while accommodating significant variations in bowl tolerances.

I sourced a proprietary PP+TPE blend material originally made for a competitor's glass bowl lids. During a visit to China, I coordinated meetings between material company representatives, lid manufacturers, and bowl manufacturers — and brought 50 pounds of the proprietary plastic to conduct sample production. The material met all tolerance specifications.

Personal Contributions

- Material Selection and Identification — tracked down custom PP and TPE blend for large tolerance sealing

- Factory and Supplier Integration — coordinated material specialists and factory leadership in China

- Statistical Tolerance Analysis — designed around production variation

- Non Linear FEA — modeled plastic lid displacement

- Strategic Mold Design — implemented slides and inserts for design flexibility