Test Fixtures

Indigo Technologies

Suspension Dyno

Role: Lead Engineer

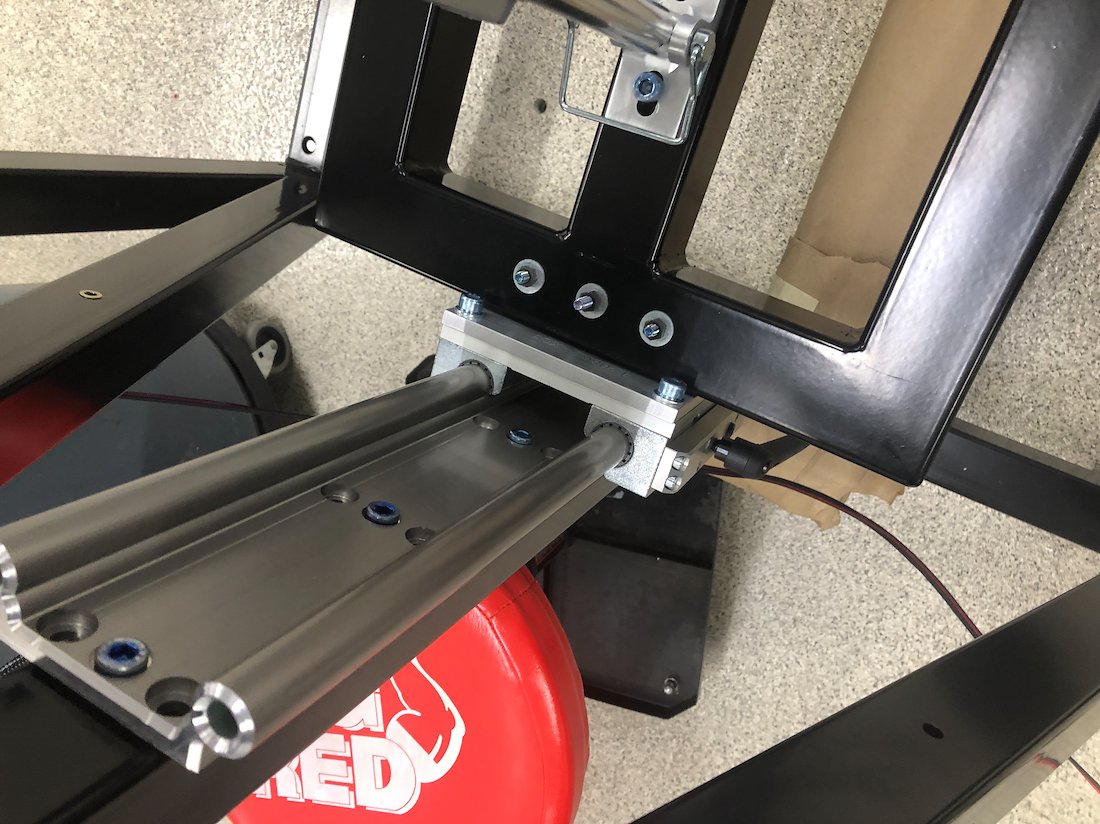

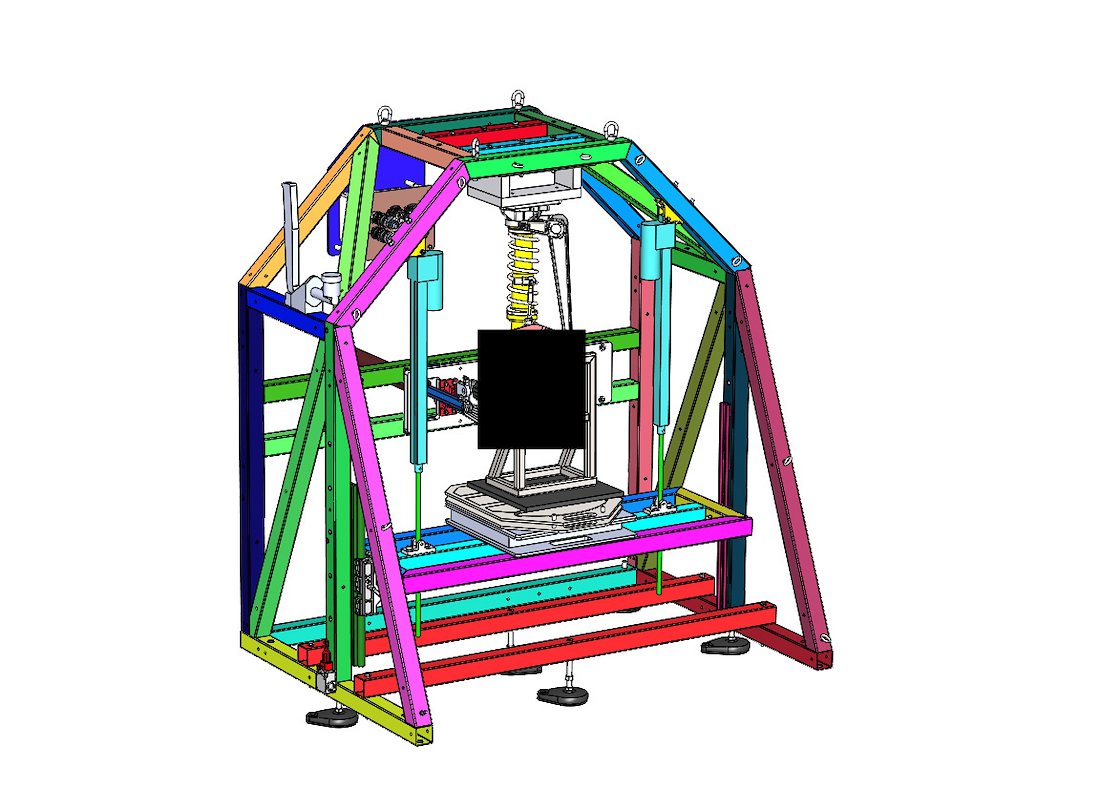

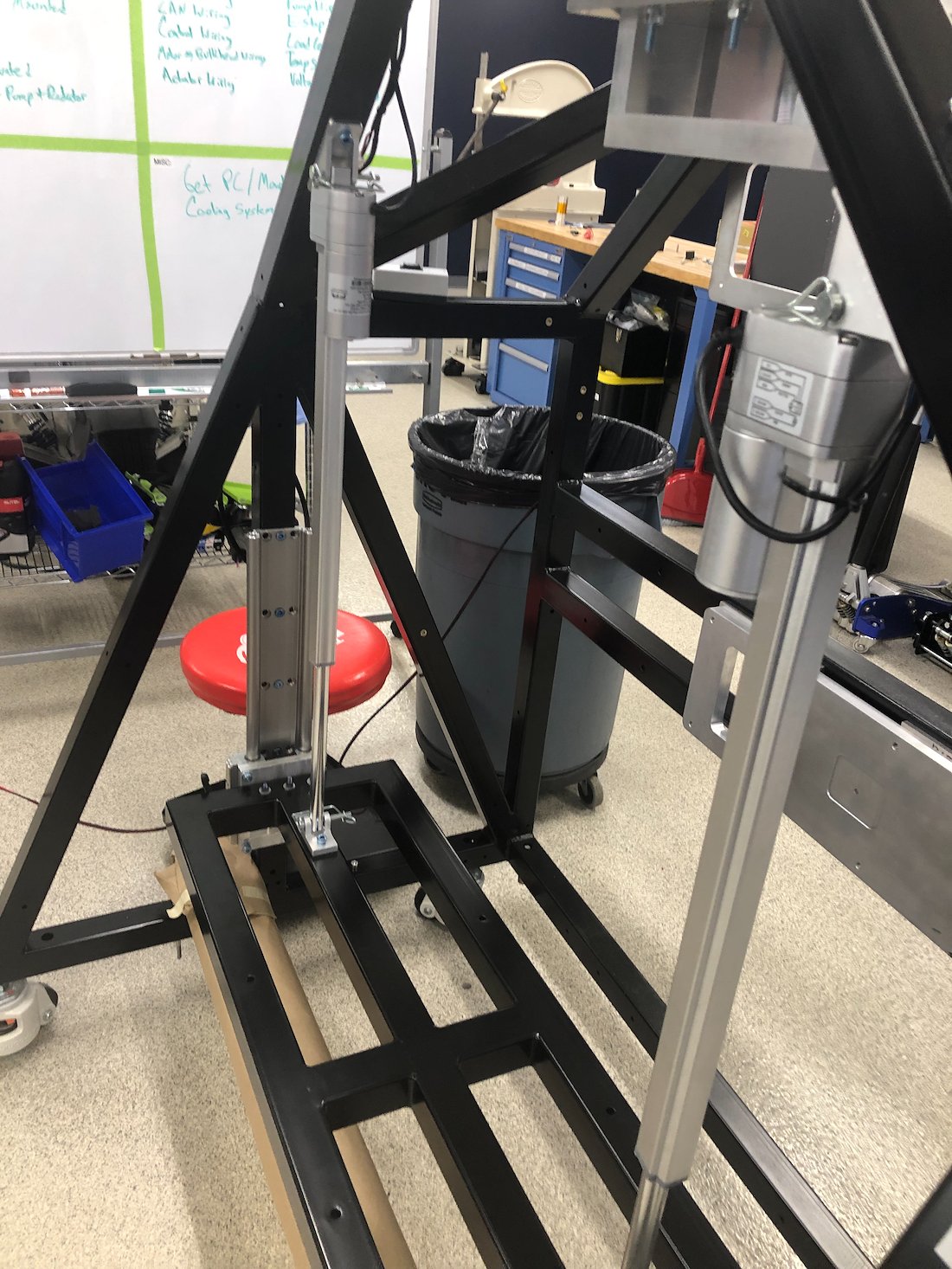

I developed a custom test stand to evaluate suspension kinematics, component lifecycle, and force output as part of vehicle and powertrain development. This project spanned approximately 2 months and involved creating a welded steel frame, movement system, and complete system integration.

The frame is designed to test suspension stiffness, so the frame is designed to deflect 0.05 mm per Newton to keep the suspension measurements highly accurate.

Rotary Dyno Upgrade

Role: Support Engineer

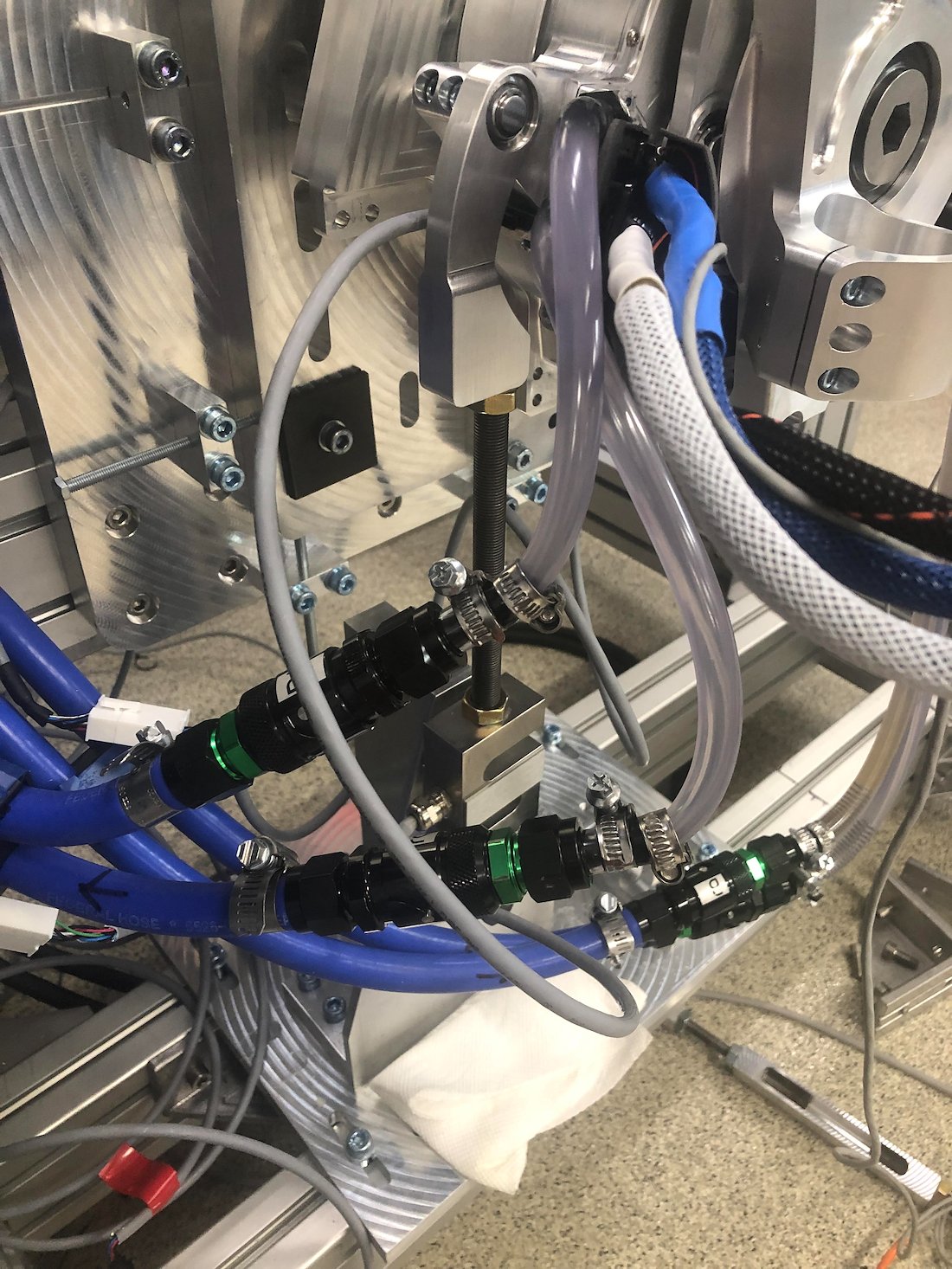

A dynamometer system measures torque and rotational speed output, calculating actual motor power. The team required custom jigging and fixture plates to mount various motor designs. I designed and constructed the fixture plate, alignment plate, torque reactor, measurement connections, and wheel bearing holders.

The most challenging part of this project was creating adjustability to keep the motor and the axle torque sensor concentric, while allowing ~200 mm of linear and ~90 degrees of adjustment around the motor with very tight clearances. The torque reaction device handles approximately 2 kN loading.