Steel Two Top Water Bottle

OXO

The Two Top bottle aimed to enhance a fashionable product functionally. People loved drinking from small openings, but hated not being able to put ice cubes in it.

I created tooling CAD from industrial design surfaces using top-down modeling. Cost management was critical since the product essentially combined two water bottles while maintaining single-bottle pricing. I analyzed manufacturing processes and negotiated with the contract manufacturer to reduce per-unit costs.

Design Challenges

- Designing two leak-proof seals

- Maintaining competitive insulation performance

- Paint color and logo selection

- Design for Manufacturability (DFM)

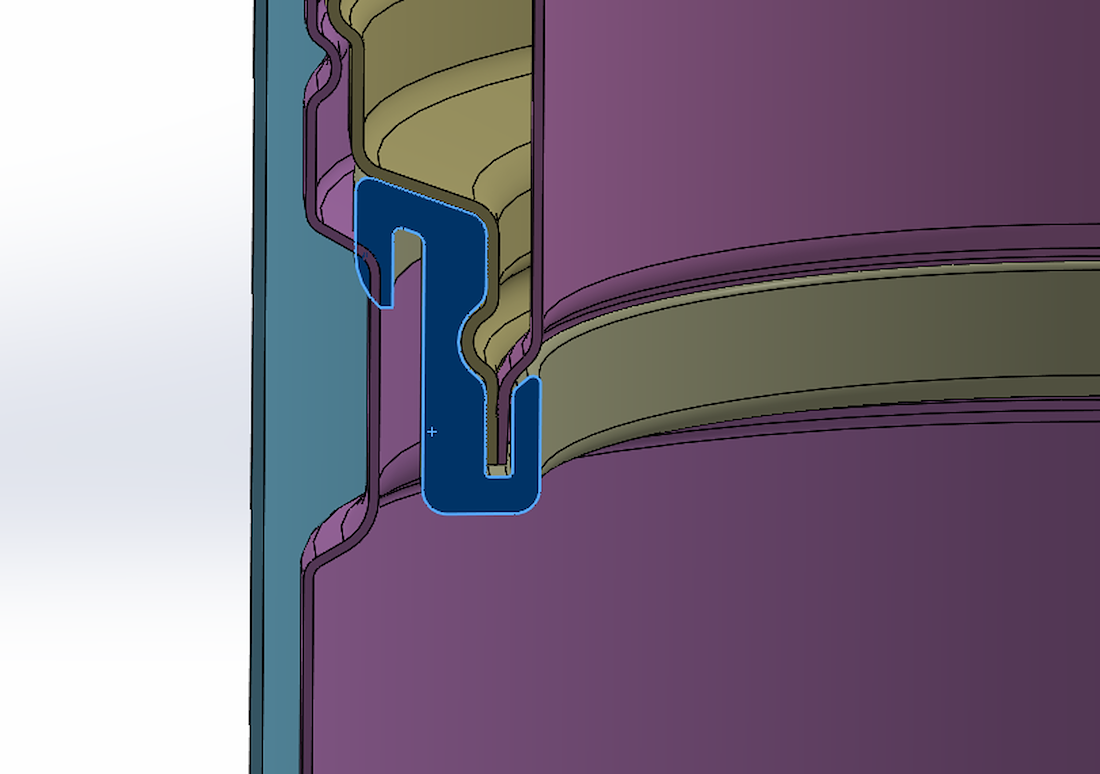

Gasket

The middle gasket required repeated deformation across a difficult-to-control surface profile while remaining connected to the upper section.

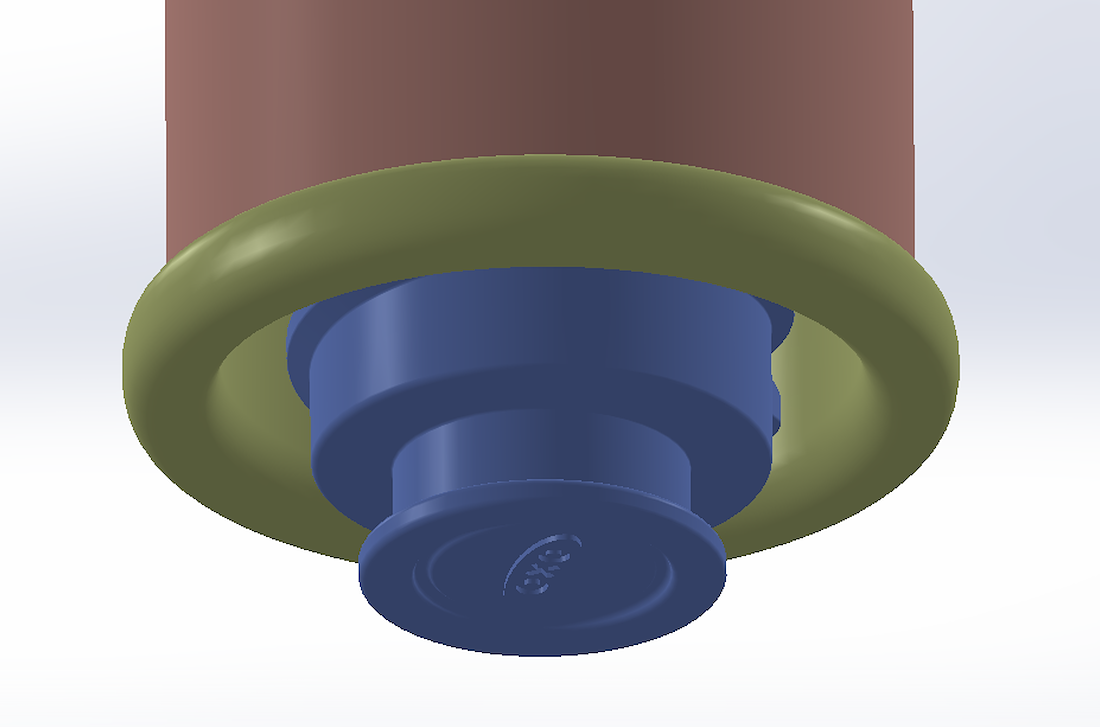

Cap

To balance manufacturability with aesthetic vision, I split the plastic into two components, overmolding the yellow section onto blue SPI threads.